Find More Low-Density Foreign Materials. Improve Quality.

Because the biggest risks are the ones you can't see.

Take Control of Food Safety and Quality Inspection

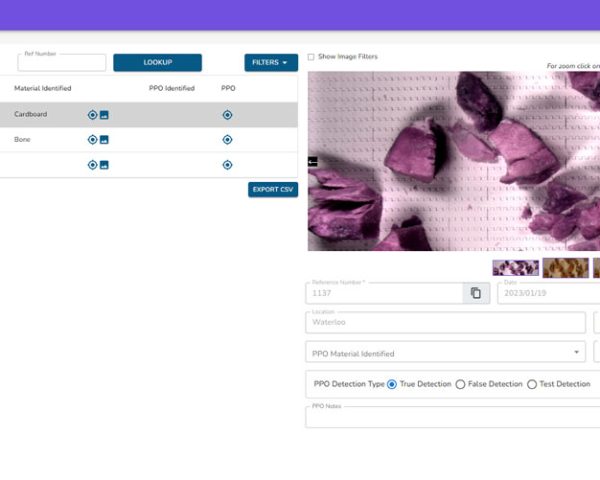

PPO’s Smart Imaging System combines hyperspectral imaging, artificial intelligence, machine learning and data analytics software to find a variety of low-density foreign materials in your product stream.

Find and Reject Contaminants

PPO’s Smart Imaging System detects and rejects foreign materials no other solution can, down to very small sizes.

Continuously Measure Quality

PPO measures fat, lean, moisture, pH and myopathies like woody breast without lab tests or offline measurements.

Identify Issues with

Real-Time Reporting

PPO Insights gives you real-time information about your product quality, processes and suppliers without compromising detection.

Deliver Safer, High-Margin Products with PPO

Understanding Hyperspectral Imaging: Choosing the Right System

When evaluating vision systems for foreign material detection in your meat processing plant you’re bound to find different solutions making similar claims. Learning how hyperspectral imaging works will help you understand why all vision technologies can’t accurately claim to offer the same strengths and capabilities.

Learn more about PPO’s Hyperspectral technology.

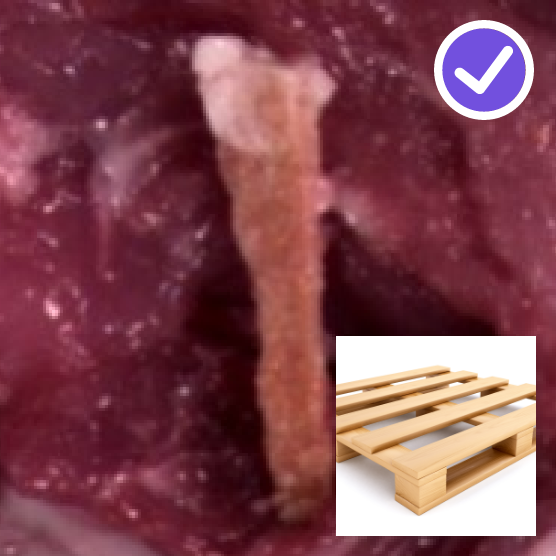

Wood

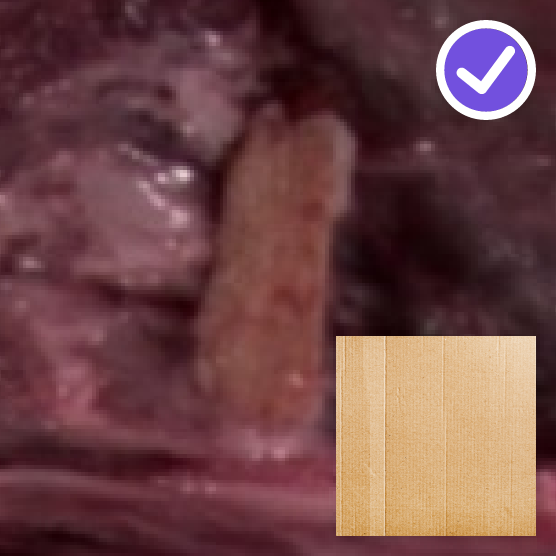

Cardboard

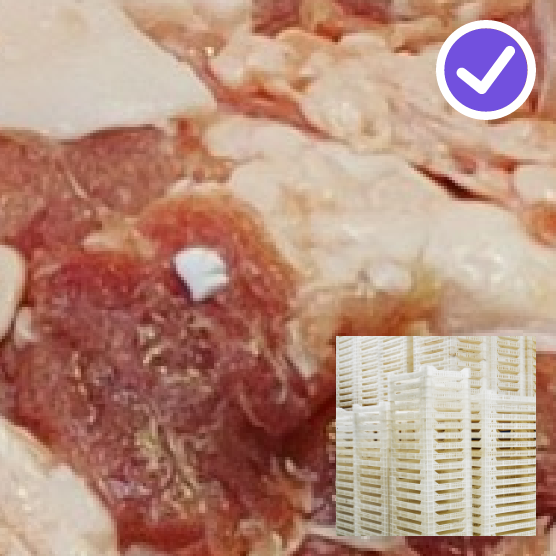

Hard Plastic

Soft Plastic

Rubber

PPE

Cotton

Bone

Smarter Food Inspection Starts Here

See more.

Hyperspectral imaging assesses the chemistry of products as they pass by at line speed. It isn’t reliant on density, color contrast or size to find foreign materials.

Analyze more.

Machine learning algorithms and AI analyze vast amounts of chemistry data and make instantaneous decisions to reject contaminated or low-quality products. This helps PPO clients rely less on manual inspection and provide consistent products.

Evaluate more.

Automatically measure fat and lean to maximize blends for a more consistent yield, without adding another piece of equipment.

Learn more.

The system continually learns and optimizes performance. Bonus: PPO Insights keeps track of incidents to provide a detailed view of what’s happening throughout your production process.

Get to Know PPO

At PPO, our technology is only part of the story—the real strength is our people. Our engineers, scientists, and support teams work side-by-side with processors to solve tough challenges and keep lines running with confidence. Driven by a mission to make meat processing safer, smarter, and more efficient, we continuously refine and develop our Smart Imaging Solution to meet the realities of the plant.

Discover How PPO is Leading the Industry in Foreign Material Detection

“We’ve had zero downstream foreign material findings since installing PPO’s Smart Imaging System”

FQSA Manager, Major Pork Processor

Let’s Work Together

PPO is ready to partner with you to deliver safer, higher quality food to your customers