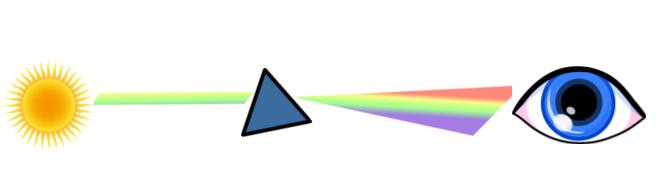

You probably remember from high school physics that light (for example, from the sun) is split into a rainbow of colours when it passes through a prism. This creates a spectrum:

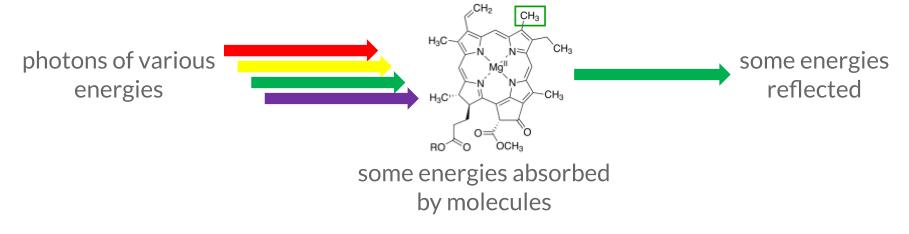

Light gives us crucial information about the material being studied. In the case of light from the sun, the spectrum shows dark bands across the rainbow of colours where specific, narrow colours of light are missing. These very specific colours, or wavelengths, of light are matched to specific chemical elements in the sun. They can be thought of as “chemical fingerprints” and they help us understand what chemical elements are found in the sun.

When the sun was first observed in this way (over 150 years ago) many of those dark bands in the rainbow could be matched to known chemical elements. But one in particular didn’t match any element known on Earth at the time. This new element was named Helium after Helios (which is the Greek word for “sun”). It would be another 60 years before the element Helium was discovered on Earth!

This act of splitting up light (or “dispersion”) is the basis of the science of spectroscopy. Spectroscopy is one of the most important, well-established, and widely-used tools in fields like astronomy, physics, and chemistry. Using this technique we can identify a wide variety of materials by looking for their chemical fingerprints in light as it is reflected from those materials.

Hyperspectral imaging is a form of spectroscopy. Hyperspectral images include full 2D spatial information (like a regular camera image) but split the light into over hundreds of continuous colours (or wavelengths)! Compare this to the 3 colours (red, green, blue) used by cameras like the one in your cell-phone. The large number of wavelengths used in hyperspectral imaging is critical to exploiting all the available information in a material. And it offers much greater precision and accuracy than older multi-colour (a few colours/wavelengths), or multi-spectral (perhaps up to a dozen wavelengths) techniques.

Hyperspectral Imaging at PPO

In PPO’s Smart Imaging System, the sun is replaced by a set of specialized lamps that generate light in visible and Near Infra-Red (NiR) wavelengths (950-1600 nm) where the spectral signatures are most sensitive to materials like meats, vegetables, and plastics. We reflect light from these specialized lamps onto the product being inspected (chicken, in the example below) as the product travels on a conveyor belt.

The reflected light is then sent through our equivalent of a prism: a high-efficiency holographic grating in our spectrometers. The information generated by the reflected light is then recorded by a high-speed camera in 500 different continuous wavelengths.

The reflected and dispersed light then contains the chemical fingerprints of anything on the conveyor belt: the belt itself, chicken, and any other materials (like plastic, wood, or rubber) which may be present. Thanks to our unique approach to hyperspectral imaging, PPO’s Smart Imaging System is more precise, accurate and sensitive than other solutions.

By feeding these hyperspectral images through PPO’s advanced machine learning software (artificial intelligence), we can examine the composition of our customer’s product as it passes through our Smart Imaging System. We can use this information to identify foreign objects in real time, at line speed. We can also use subtle differences in the chemical fingerprints of the product itself, to understand information like fat/lean content, tenderness, freshness, pH and more. And we can adjust on the fly to get new information from the same spectral data, tailored to our customers’ specific applications and requirements.

Advances in hyperspectral imaging and computer processing make it possible for PPO’s Smart Imaging System to address some of the biggest and most important issues in a food processing plant. Ready to learn more about how PPO can help you deliver safer, healthier food to your clients? Contact us today.