Deliver Safer, Higher Quality Products with PPO

We help meat processors detect low-density foreign objects and ensure quality.

PPO’s Smart Imaging Systems use hyperspectral imaging with AI and machine learning to analyze product chemistry in real-time at line speed.

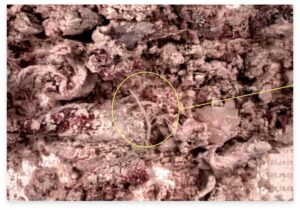

Find Low-Density Foreign Materials. Stop Recalls Before They Happen

Our automated system inspects each product for quality and foreign materials before it leaves your facility.

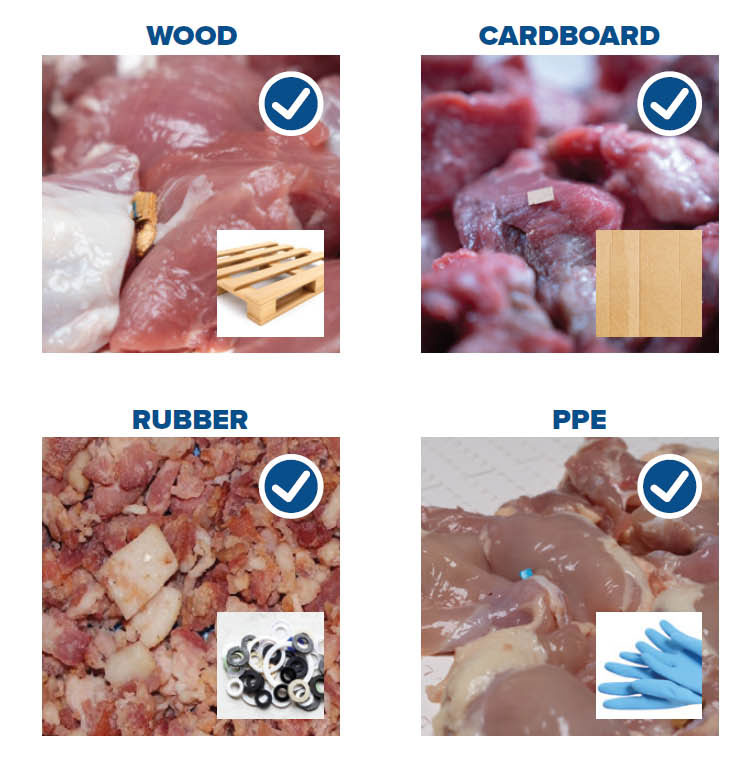

PPO Smart Imaging Systems can see and classify many hard-to-find foreign materials including those that can’t be found by other solutions. Our system finds:

- Rubber Glove

- Wood

- Cardboard

- Combo Liner

- Stainless Steel

- Polyethylene

- Polypropylene

- Acetal

- Thermoplastic

- Cotton Glove

- And more!

Measure Lean Point

Limit offline spot testing!

With PPO you can accurately measure lean point in-line, on every pound of product you process.

PPO will measure the percentage of both fat and lean in your products, with no estimations or calculations!

With PPO, your lean point will be based on chemistry, not on approximations.

Find and Remove Woody Breast

Muscle myopathies like woody breast are easy to find when you assess chemistry. PPO’s proven technology can consistently identify and remove the most severe woody breast from your stream.

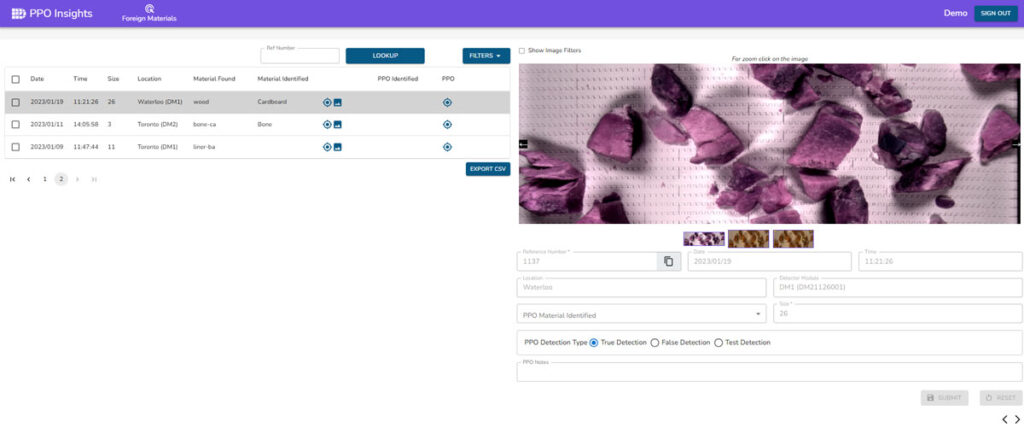

Get Real-Time Data About Your Production

PPO’s Smart Imaging System sees the chemical makeup of your products as they pass by at line speed. We capture and process this information in real time using hyperspectral imaging, combined with artificial intelligence and machine learning models.

In production, PPO’s system makes over 16 million decisions every minute, identifying issues in real time, pixel by pixel. As your products are processed, PPO’s systems continue to learn and optimize performance over time. For example, new foreign materials found by the system can be labeled and classified in future models – allowing PPO to continuously improve your system’s performance. Incidents captured by PPO’s system are stored and presented in PPO Insights, where you can review and analyze what’s happening with your products over time.

Many Products, One Solution

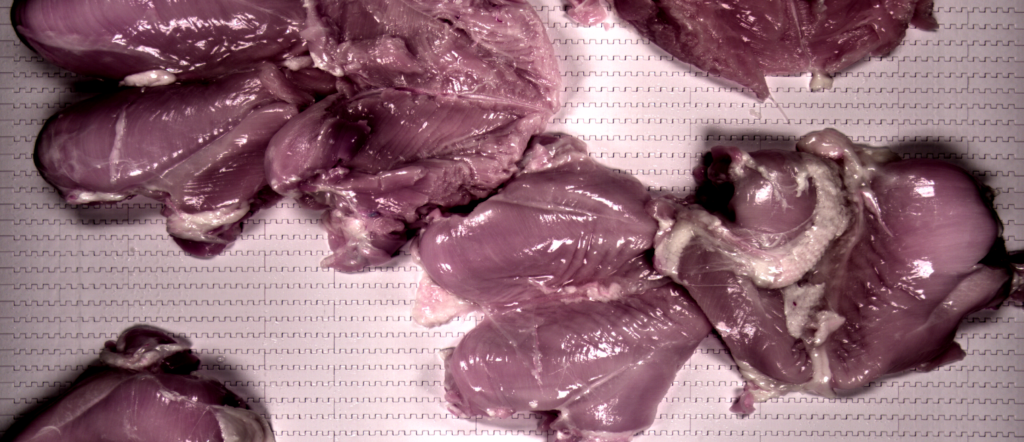

PPO’s Smart Imaging System works with many different protein products

Pork Products

- Trim (outgoing from harvest/incoming for production)

- Bacon slices (cooked/cured)

- Bacon bits (cooked/pre-cooked)

- Grinds (coarse and fine)

- Whole muscle grading

Poultry Products

- Whole muscle (breast and thighs)

- Trims (tenders, nuggets pieces, breast trim etc.)

- Cooked/parfry products

- Slice and dice

Pet Food Products

- Raw materials inspection

- End of line foreign material detection

Resources

- Industry Brief, Pork

Delivering consistent, high-quality product while managing costs and ensuring food safety requires best-in-class automated detection of foreign materials.

- Industry Brief, Poultry

Poultry processors want to deliver safe, high-margin product, but foreign material contamination can damage customer relationships and cause costly recalls.

- Case Study

A meat processor’s new PPO Smart Imaging System proved it’s effectiveness by detecting and rejecting hidden contaminants in a batch of raw materials.

Let’s Work Together

PPO is ready to partner with you to deliver safer, higher quality food to your customers