Chemistry, AI and Hyperspectral Imaging. Unmatched Insights.

By combining advanced chemistry with Al, PPO’s technology enhances food safety and quality, offering deeper insights into critical factors like lean point and woody breast. It empowers plants with a robust understanding of product quality, enabling smarter decisions and stronger supplier negotiations.

PPO: The Only Solution That Combines Deep Chemistry Insight with Meat Processing Expertise

With over 20 years of pioneering research in high-performance spectroscopy, PPO leads the market in hyperspectral imaging technology. Our systems are deployed in meat processing facilities in North America, Europe and Australia, where they detect and eliminate foreign materials with unmatched precision. PPO analyzes in-line chemical data and empowers processors to optimize resource use, fine-tune operations, and effectively manage supplier performance.

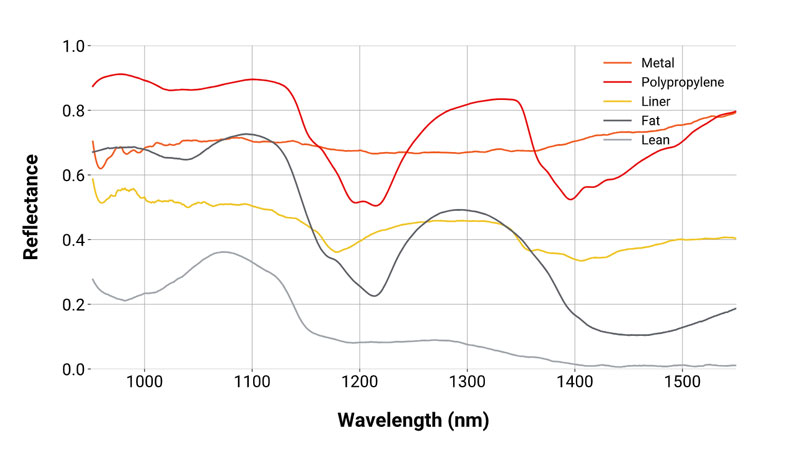

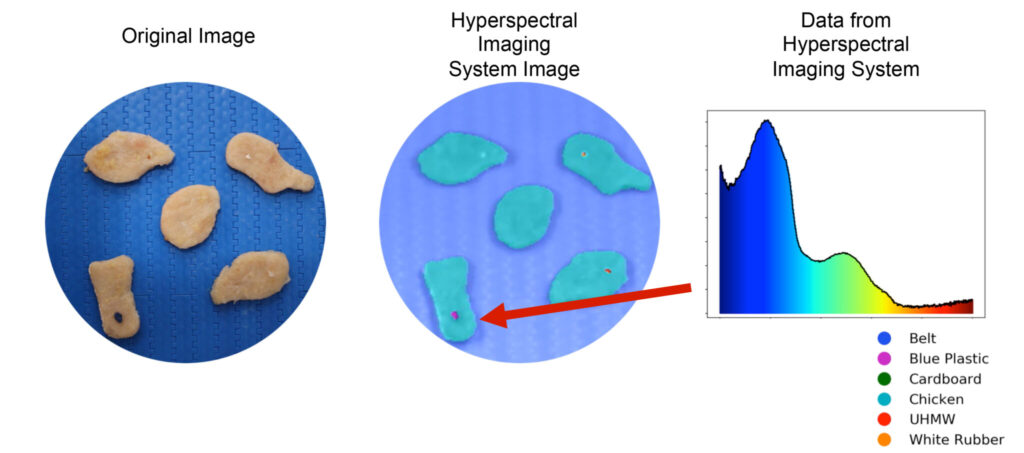

Hyperspectral imaging technology analyzes products by capturing and processing light across hundreds of wavelengths. This allows the system to detect subtle differences in the chemical makeup of materials, identifying foreign objects and assessing product quality in real-time without relying on density or color contrast.

PPO’s patented spectrometers deliver unmatched data quality and speed, ensuring accuracy every time.

Measuring chemistry allows you to assess food quality characteristics like lean point.

PPO’s unique machine learning algorithms generate real-time analysis of vast amounts of chemistry data. That means our system can make instantaneous decisions to remove contaminated or lower-quality product.

How Does Hyperspectral Imaging Work in Meat Processing?

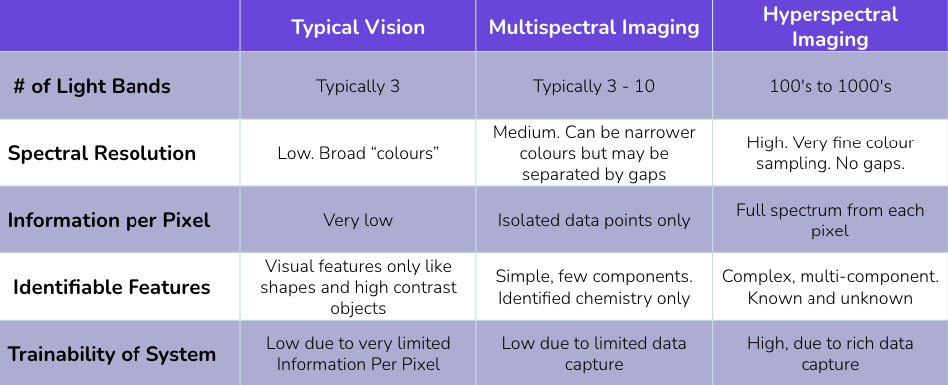

When evaluating vision systems for foreign material detection in your meat processing plant you’re bound to come across different solutions making similar claims. Learning how hyperspectral imaging works will help you understand why all vision technologies can’t accurately claim to offer the same strengths and capabilities.

Hyperspectral imaging is a form of spectroscopy. You can think of it like a camera, but the similarities end there. A typical camera image only uses three colors (red, green and blue) and even multispectral images only use up to a dozen colors. In contrast, hyperspectral images split the light reflected off product into hundreds of continuous colors (or wavelengths). This offers multiple benefits:

- More precision. The large number of wavelengths used in hyperspectral imaging allows the technology to capture and use all the available information in a material.

- More accuracy. Hyperspectral imaging offers more exact detection than other methods.

- More capabilities. It also allows the technology to “see” the chemistry of the food it inspects. This helps to find low-density materials without depending on density, color contrast or size. It also helps with assessing food quality characteristics like lean point.

Here’s how the tech comes to life in our Smart Imaging System:

Here’s how the tech comes to life in our Smart Imaging System:

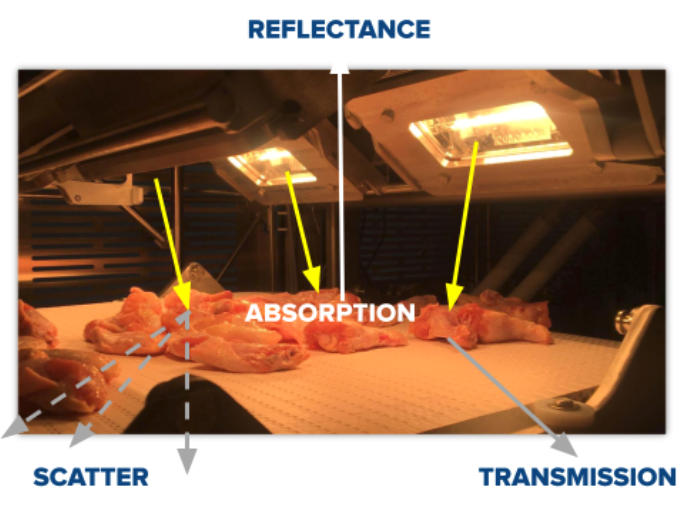

- A set of specialized lamps generates light in both visible and Near Infra-Red (NIR) wavelengths where the spectral signatures are most sensitive to materials like meats, vegetables and plastics.

- Light from these specialized lamps is reflected onto the product being inspected as it moves along the conveyor belt.

- The reflected light is sent through a high-efficiency holographic grating inside our patented spectrometers. The information generated by the reflected light is recorded by a high-speed, high-resolution camera in 500 different continuous wavelengths.

- The reflected and dispersed light contains the chemical signature of anything on the conveyor, including the belt, product and any other materials (like plastic, wood or rubber) present.

Watch our Behind the Scenes video: "The Science Behind Hyperspectral Imaging in Simple Terms"

Measuring the Return on Investment in Inspection Technologies

Retain Customers – What’s the cost of losing one or more customers?

Features of PPO Software:

- Real-Time Decision Making: Instant identification of contamination, quality variations, and other issues.

- Customizable Insights: Tailored to meet the unique needs of each processing line.

- Seamless Integration: Easily integrates with your existing systems for smoother operations.

- Advanced Reporting: Provides detailed analytics to optimize processes and reduce waste.

- SOC 2 Compliant: Ensuring your data is safe and secure.

Enable Premium Pricing: Can you improve margins by providing higher-quality product?

Labour Savings ($): Reallocate staff currently required for inspection tasks.

Reduce Food Waste ($$): Discard a combo instead of half a day’s production.

Reduce Downtime: Avoid equipment damage and downstream FM incidents.

Prevent Chargebacks: Reduce chargebacks due to defective products shipped to customers.

Turning Data into Actionable Insights – AI and Machine Learning

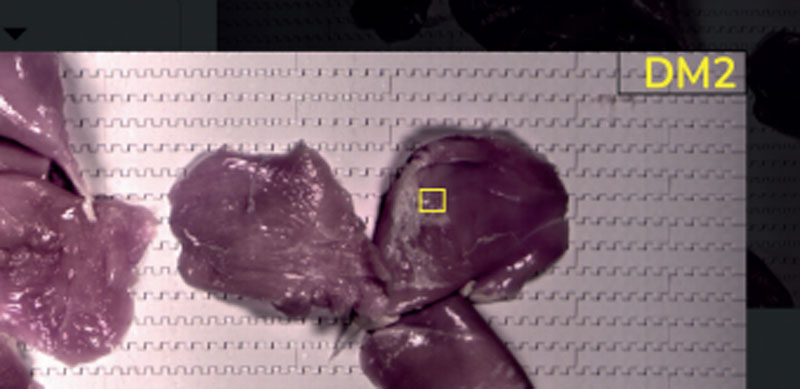

Feeding hyperspectral images through PPO’s advanced machine learning software allows for highly sensitive inspection of your product as it passes through the Smart Imaging System.

When in operation, PPO’s system makes over 16 million decisions every minute, identifying issues in real time, pixel by pixel. Our software transforms hyperspectral data into actionable insights for food processors. Using advanced machine learning models and AI algorithms, PPO’s software analyzes the rich data collected by our hyperspectral systems to deliver real-time, actionable results. Our models are continuously updated improving inspection accuracy over time. Working with PPO’s Smart Imaging System, PPO Insights offers a user-friendly dashboard to track and report on quality metrics and foreign material incidents.

Features of PPO Software:

- Real-Time Decision Making: Instant identification of contamination, quality variations, and other issues.

- Customizable Insights: Tailored to meet the unique needs of each processing line.

- Seamless Integration: Easily integrates with your existing systems for smoother operations.

- Advanced Reporting: Provides detailed analytics to optimize processes and reduce waste.

Want to Learn More?

Let’s Work Together

PPO is ready to partner with you to deliver safer, higher quality food to your customers