PPO Waterfall Elite System

Protect your product from contamination with a detection system designed for maximum performance and minimal footprint.

Industry-Leading Foreign Material Detection in a Smaller Footprint!

The Waterfall Elite is the latest addition to our industry-leading hyperspectral imaging systems, designed specifically for meat processors. Delivering the same reliable performance as PPO’s Waterfall configuration, this system offers a smaller footprint, making it ideal for facilities with limited space.

Compact and Powerful

This system is the ideal solution for processors of chunked or ground products, bacon bits, and other small-form items with limited space. The Waterfall Elite is specifically designed to fit seamlessly into compact processing lines without sacrificing detection capabilities. The streamlined design enables seamless integration with your current setup, helping you maintain peak operational efficiency.

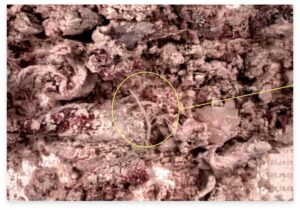

The detection capability is the same as PPO’s other systems, including two-sided inspection over the waterfall. The system detects and removes challenging foreign materials—such as plastics, rubber, cardboard, and wood—at the same small particle sizes handled by all PPO systems.

Like PPO’s Z-Configuration system, this system includes one rejection at the end of the outfeed.

Built For The Plant

- Allows for efficient cleaning in place

- Watertight design with seals and seams proven to withstand all common cleaning practices in meat, poultry and pet food plants

- Adjustable height – raised off the floor for easier inspection and cleaning

- Includes separate HMI enclosure

- Adjustable belt guides

- Connects easily to 3rd party sorting devices and 3rd party belting

- Offers the Intralox Series 1100 flat top X-ray detectable white acetyl belt

- Features zero harborage points

- Meets all applicable food-safe sanitary design principles and standards, including NAMI and CFIA, and is IP69K compliant

- Features a fully enclosed imaging & materials handling area with safety interlocks

- SOC 2 Compliant to keep your data secure

Key Benefits of the Waterfall Elite System

Enhanced Foreign Material Detection

Compared to traditional technologies, our systems can detect smaller and a broader range of foreign materials, including plastic, rubber, bone and wood. By catching contaminants early, we help reduce recalls, prevent chargebacks, and keep your customers happy.

Comprehensive Quality Control

Get real-time insights into product quality, from lean-to-fat ratio to color and texture, as processing happens. Ensure every product meets customer expectations and stays consistent, batch after batch.Big Performance in a Smaller Footprint

This smaller-footprint configuration is ideal for foreign material detection and lean point measurement on ground or diced poultry, pork trims, coarse grinds of beef or pork trims, and bacon bits.

Advanced Data Analytics

Unlock actionable insights with our powerful analytics platform. Understand trends, pinpoint root causes, and continuously improve your operations. Plus, detailed reports on performance and detection help you plan smarter for the future.Additional Resources

- Tech Brief

A head-to-head comparison of inspection modalities like X-ray, camera vision system and hyperspectral imaging across different types of materials.

- Industry Brief

Producing bacon products puts meat processors at higher risk for recalls making it imperative to reduce the chance of harmful foreign materials getting to the end customer.

- Case Study

A meat processor’s new PPO Smart Imaging System proved it’s effectiveness by detecting and rejecting hidden contaminants in a batch of raw materials.

Let’s Work Together

PPO is ready to partner with you to deliver safer, higher quality food to your customers