PPO Insights: Optimize Your Production with Real-Time Data

With machine learning and big data, you can unlock rich chemical data that helps you

optimize production and manage your suppliers more efficiently.

With machine learning and big data, you can unlock rich chemical data that helps you

optimize production and manage your suppliers more efficiently.

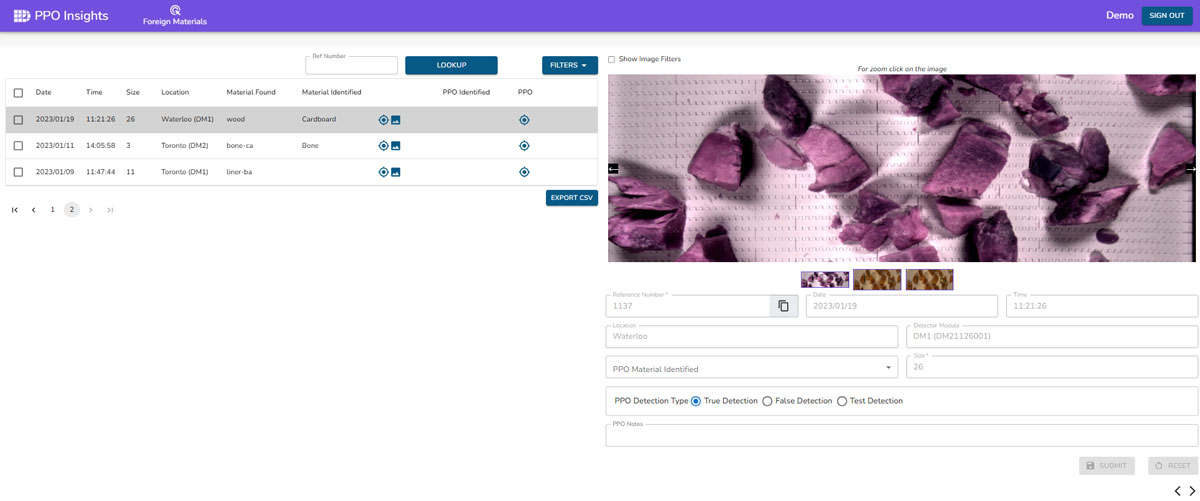

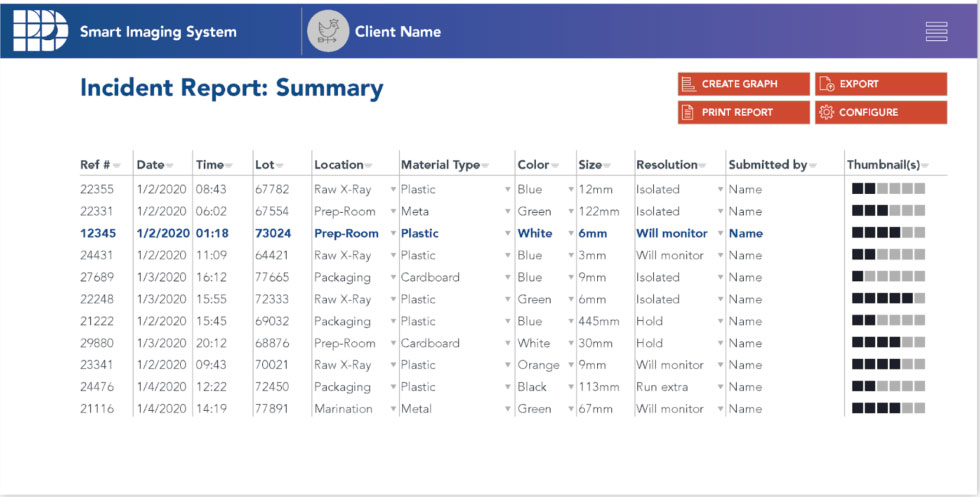

PPO Insights delivers real-time information and reporting based on what’s happening on the line.

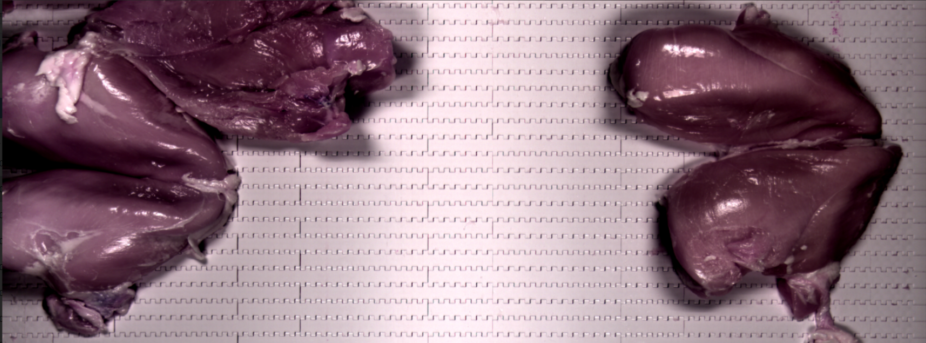

Working with PPO’s Smart Imaging System, PPO Insights offers a user-friendly dashboard to track and report on quality metrics and foreign material incidents.

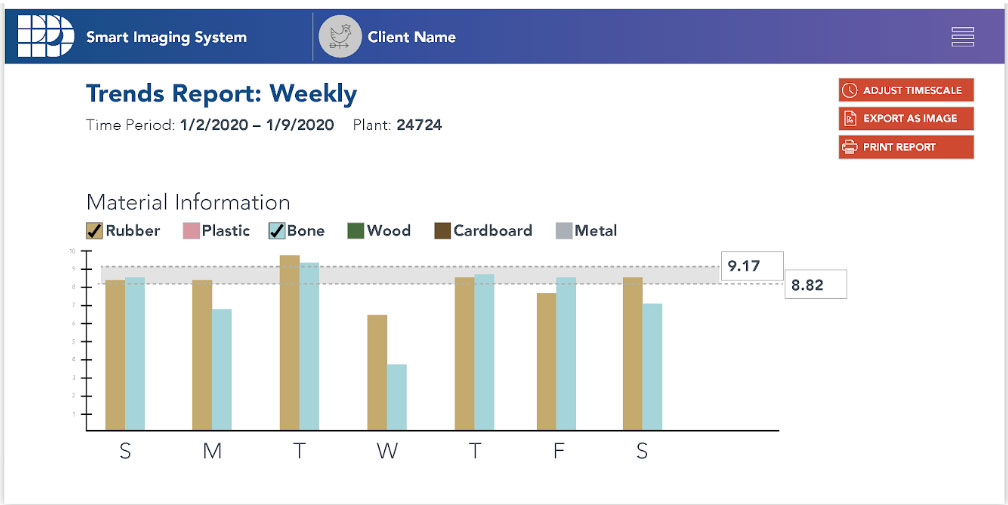

The rich chemical data captured by our system can be used to optimize your production and manage your suppliers. Over time, this information can be used from farm to fork, influencing everything from feeding practices and transportation to quality and safety information shared with your customers.

Highlight trends in

incidents of foreign material contamination or quality issues, pointing out possible areas of process improvement or optimization.

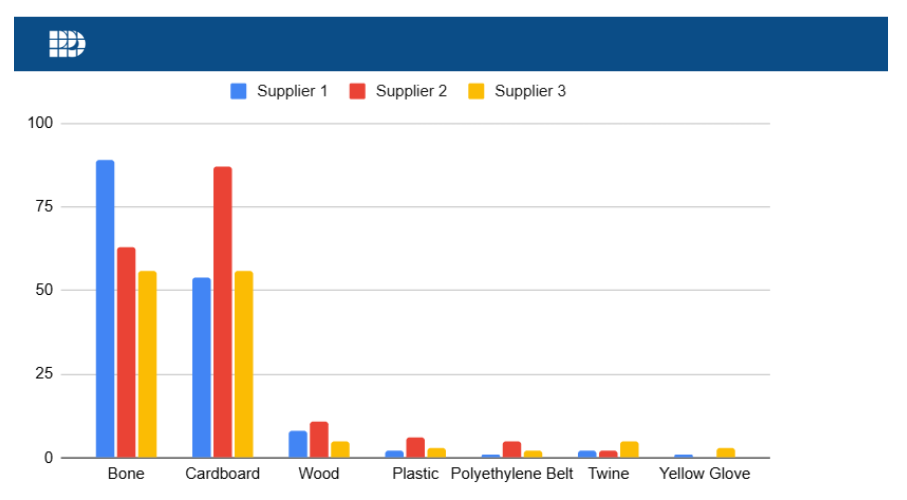

PPO’s system will identify the specific materials involved in each incident so those contaminants can easily be traced to the source. Identify issues by supplier with digital records and reports that are easy to download and share.

Get reports that can be easily shared with your clients, demonstrating your proactive and thorough approach to ensuring compliance with their specifications.

Identify issues by supplier and uncover unexpected insights, with digital records and reports that are easy to download and share. PPO’s AI engine and insights platform make our system flexible and intelligent enough to meet our customers’ precise needs and plant operating decisions, both now and well into the future.

Features and Benefits:

PPO is ready to partner with you to deliver safer, higher quality food to your customers